MIL-DTL-19264C (OS)

4.6.1 Chemical analysis. The chemical composition shall be determined using the methods specified

in Table III. The requirements of 3.2 shall be met or the lot shall be rejected.

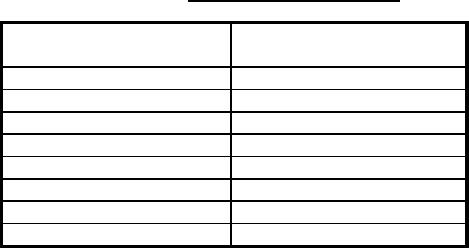

TABLE III. Chemical analysis test methods.

Material

Test Method of MIL-STD-286

Nitrocellulose

209.2.1

n-Butyl Stearate

222.1

Ethyl Centralite

202.2.3

Basic Lead Carbonate

311.1.3 or 316.1

Potassium Sulfate

310.3.1, 310.4.2, or 316.1

Moisture

103.5

Total Volatiles

103.5

Graphite

308.1.4

4.6.2 Grain dimensions. Grain dimensions shall be determined in accordance with MIL-STD-286,

method 504.1.1 or 504.6.1. The requirements of 3.3 shall be met or the lot shall be rejected.

4.6.3 Visual examination. The propellant grains selected for the physical characteristic tests shall be

visually examined prior to conducting the physical characteristic tests (4.6.1 and 4.6.2) to verify that:

a. Grain form conforms to the requirements of 3.3.

b. Grains are uniformly coated with graphite, conforming to the requirements of 3.4.

c. Workmanship conforms to the requirements of 3.10.

4.6.4 Stability. Stability shall be determined in accordance with MIL-STD-286, method 404.1.2

(134.5°C heat test). The requirements of 3.6 shall be met or the lot shall be rejected.

4.6.5 Packing depth. Prior to all maximum packing depth (MPD) pour testing the propellant shall be

conditioned for a minimum of four days at 90 ± 3° Fahrenheit (F). The MPD is the distance, measured to

the nearest tenth of an inch, from the case mouth to the upper level of any given propellant charge in a

loaded cartridge case. The PPD is the MPD, less the empirical value of 0.7 inches, in the MK 9 cartridge

case. MPD is determined by pouring the propellant charge steadily from a height of 30 inches above the

mouth of a primed case, over an interval of sixty (60) seconds while the outside of the case is briskly

tapped with a soft mallet adjacent to the rising level of the propellant during pouring. The MPD shall be

determined for each lot of propellant by pouring three (3) different charge weights, spanning the expected

assessed charge weight range, three (3) times each for a total of nine (9) pours. The MPD for each of the

nine (9) pours shall be recorded and a curve should be fitted to the PPD values derived from the MPD

pouring data to allow for interpolative prediction of the PPD. Subsequent to acceptance tests of each lot

of propellant, the assessed charge shall be poured a minimum of three times to determine the MPD and

the resultant PPD.

4.6.6

Ballistic testing.

4.6.6.1 Warming or conditioning rounds. Warming or conditioning rounds shall be fired to stabilize

gun temperature and eliminate the biasing effects of firing the propellant at various charge levels or

temperatures. The first round fired in a gun during a test is the warming round. The round fired as part of

a temperature conditioning group or charge level group wherein the velocity is expected to differ from the

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business