MIL-DTL-19264C (OS)

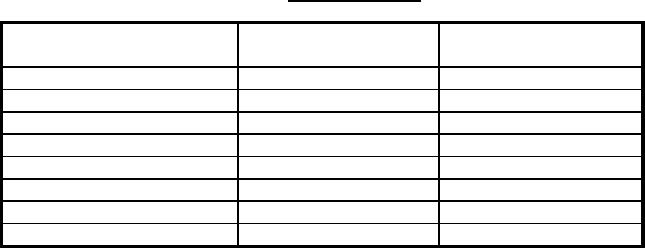

TABLE I. NACO composition.

Material

Specification

Percent by Weight

MIL-DTL-2441/

Nitrocellulose, Grade E, Type I

93.55 (nominal)

MIL-B-214652/

n-Butyl Stearate

3.00 ± 0.30

Ethyl Centralite, Class 2

MIL-E-255

1.20 ± 0.20

MIL-L-186183/

Basic Lead Carbonate

1.00 ± 0.20

Potassium Sulfate, Type I

MIL-P-193

1.25 ± 0.30

Moisture

-

1.00 (min) to 3.00 (max)

Total Volatiles

MIL-STD-652, Figure 1

5.0 max

Graphite, Grade IV

MIL-G-155

0.10 ± 0.05

1/ The nitrocellulose shall have an average nitrogen content of 12.00 ± 0.10 percent, and shall

have a viscosity of 5 ± 2 seconds. The required nitrogen content may be obtained by blending

nitrocellulose containing 11.90 to 12.20 percent nitrogen. Average nitrogen content

determination shall be made only when specifically requested in the contract (see 6.2).

2/ The n-butyl stearate specific gravity shall be determined at 25°C/25°C and the sample weight

shall be 2.5 to 3.2 grams for iodine test.

3/ The compatibility tests for lead carbonate with Cordite-N propellant shall not be performed.

Stability (C1). Using the 134.5° Celsius (C) heat test, the methyl violet test paper shall not fade

3.6

to a salmon-pink color in less than 40 minutes and the propellant shall not self initiate in less than 5 hours

(see 4.6.4).

Packing depth (M103). The minimum production packing depth (PPD) of the assessed charge

3.7

weight shall be 3.5 inches (measured from the case mouth) (see 4.6.5).

3.8

Gun ballistic assessment requirements.

3.8.1 Velocity (M104). The charge weight of the test propellant (TP) shall be assessed to result in a

nominal average projectile muzzle velocity matching that obtained for the reference propellant (RP) via

the powder proof firings (see 4.6.6.3.2).

3.8.2 Pressure (M105). The maximum allowed chamber pressure shall be 55,100 pounds per square

inch (psi) (see 4.6.6).

3.8.3 Velocity variation (M106). The maximum allowed projectile muzzle velocity standard deviation

shall be 10 feet per second (ft/sec) (see 4.6.6).

3.8.4 Pressure variation (M107). The maximum allowed chamber pressure standard deviation shall

be 1,700 psi (see 4.6.6).

Propellant interface test. All first article lots shall be subjected to the propellant interface test.

3.9

Production lots shall be subjected to the propellant interface test when directed by the procuring activity

(see 4.6.9 and 6.5).

3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business