MIL-DTL-82901A(OS)

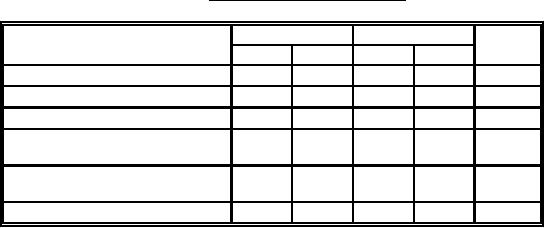

TABLE II. Cured explosive requirements.

Type I

Type II

Test

Property

Min.

Max.

Min.

Max.

Method

Density at 25°C (g/cc)

1.62

1.70

1.62

1.70

4.6.1

Stress, max., at 25°C (psi)

20

--

20

--

4.6.2

Strain, max. stress at 25°C (%)

10

--

9

--

4.6.2

Hardness, Shore A, 15 second

15

--

20

--

4.6.3

delay at 25°C

Vacuum stability at 100bC (mL gas

--

0.4

--

0.4

4.6.4

per g per 48 hours)

Average composition, % HMX

86

89

86

89

4.6.5

3.5 Thermal stability (first article only). The thermal stability of cured PBXN-110 shall be tested

in accordance with 4.6.6.

3.6 Workmanship. The explosive material shall be free from contamination with extraneous

materials and manufactured in a manner to assure compliance with this specification. The sample shall

then be evaluated to determine acceptability and the approved standards of workmanship will thereby

become a minimum requirement for all units offered for acceptance.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as

follows:

a. First article inspection (see 4.4)

b. Conformance inspection (see 4.5)

4.2 Inspection conditions. Unless otherwise specified, all inspections shall be performed in

accordance with the test conditions specified in the applicable inspection paragraph.

4.3 Approval of new ingredient vendors. When a new vendor of a PBXN-110 ingredient (see table

I) is proposed for use, the ingredient shall be evaluated in PBXN-110 according to an approved test plan.

Section 6.8 provides guidance on this test plan. Alternate test plans may be used if approved by the PBXN-

110 Configuration Control Board. Further, the government reserves the right to require re-approval of an

ingredient vendor who makes a major change to their process or has not produced the material for over one

year. Sufficient material from each of the number of lots of the ingredient, as specified in table III, shall be

forwarded to the activity designated by the procuring activity so that a batch or batches of PBXN-110 can

be made and tested as specified in table III. The approval evaluation batch or batches may be smaller in

size than that used in production. The PBXN-110 Configuration Control Board shall review the ingredient

test results and determine whether the sample is approved or rejected. Approved ingredient vendors are

listed in section 6.9.

4.4 First article inspection.

4.4.1 First article inspection. The first article sample shall be manufactured using the same process,

procedures, and ingredient vendors proposed for production, and inspected for the requirements of 3.4 and

3.5. This sample shall be tested in accordance with the test procedures specified in 4.6.1 through 4.6.6

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business