MIL-DTL-82901A(OS)

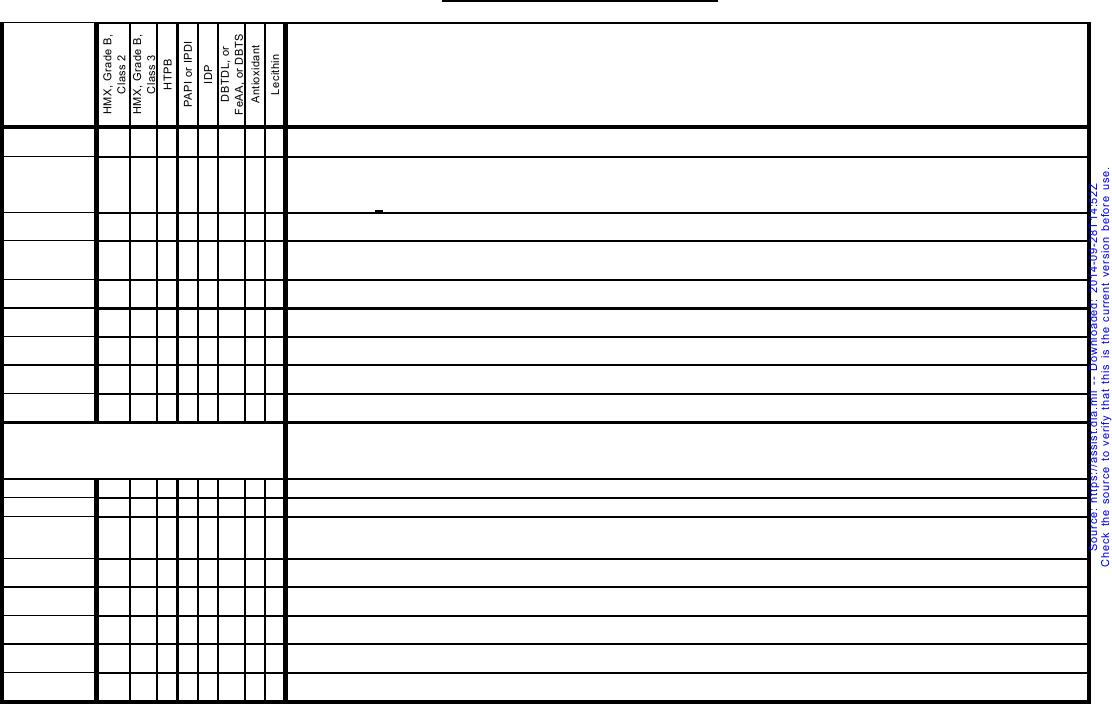

TABLE III. Approval tests for new ingredient vendors.

New Vendor's

Ingredient:

TEST

TEST METHOD

PBXN-110

XX

XX X

X

X

X

X

X Test in accordance with 4.6.1 through 4.6.5.

Spec. Analysis

Processing

XX

XX X

X

X

X

X

X Prepare a PBXN-110 batch at least two pounds in size. Fill a 500-mL beaker with PBXN-110 immediately following the end of mix. Measure the

Evaluation

viscosity with a t-spindle viscometer and helipath stand at the end of mix and every half hour for a minimum of 5 hours. Record and report the viscosity

data along with the viscometer type, spindle type and speed used, choosing the correct types and speeds for PBXN-110. Keep the sample at constant

temperature (20 + 2°C) throughout the evaluation.

Shock

XX

XX

Test a cured PBXN-110 sample in accordance with MIL-STD-1751, Method 1041.

Sensitivity

Impact

X

X

Test a cured PBXN-110 sample in accordance with MIL-STD-1751, Method 1012, or Rotter impact sensitivity test may be conducted in accordance with

Sensitivity

STANAG 4489. Concurrently test an RDX Type II Class 5 sample as a standard.

Friction

X

X

Test a cured PBXN-110 sample in accordance with MIL-STD-1751, Method 1021 or 1024, with an RDX Type II Class 5 sample as a standard.

Sensitivity

ESD

X

X

Test a cured PBXN-110 sample in accordance with MIL-STD-1751, Method 1031 or 1033, with an RDX, Type II, Class 5 or PETN sample as a

Sensitivity

standard.

Thermal

X

X

X

X

Test a cured PBXN-110 sample in accordance with 4.6.6.

Stability (DSC)

Critical

X

X

Test a cured PBXN-110 sample in accordance with MIL-STD-1751, Method 1091.

Diameter

Thermal

X

X

X

X

Test a cured PBXN-110 sample in accordance with ASTM E 831.

Expansion

Age the PBXN-110 samples for the aging tests listed below for six months at 70°C. The PBXN-110 Configuration Control Board may allow a shorter

Aging

aging period on a case-by-case basis, pending review of the ingredient vendor change. Conduct the following tests on cured PBXN-110 at the

(6 mos. @ 70 C)

beginning and end of aging (note exceptions). Where more than one test method may be used, use the same test method for both tests (before and

after aging).

VTS

X

X

X

X

X

X

Test in accordance with 4.6.4.

Composition

X

X

X

Test in accordance with 4.6.5.

Mechanical

X

X

X

X

Test in accordance with 4.6.2. Test at 0, 3 and 6 months.

Properties

(Stress/Strain)

Thermal

X

X

X

X

X

X

Test in accordance with 4.6.6.

Stability (DSC)

Impact

X

X

Test in accordance with MIL-STD-1751, Method 1012, or Rotter impact sensitivity test may be conducted in accordance with STANAG 4489.

Sensitivity

Concurrently test an RDX Type II Class 5 sample as a standard.

Friction

X

X

Test in accordance with MIL-STD-1751, Method 1021 or 1024, with an RDX Type II Class 5 sample as a standard.

Sensitivity

ESD

X

X

Test in accordance with MIL-STD-1751, Method 1031 or 1033, with an RDX, Type II, Class 5 sample as a standard.

Sensitivity

Shock

X

X

Test in accordance with MIL-STD-1751, Method 1041.

Sensitivity

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business