MIL-DTL-82901A(OS)

The NCO/OH ratio shall be calculated using the equivalent weights of materials obtained by chemical

analysis using the techniques of 4.6.1 of WS 22348, 4.5.2 of WS 16305, and 4.6.2 of WS 23148. To avoid

shelf life problems with component materials, this chemical analysis must be conducted at least every six

months on lots of materials being used. The weight percent of each ingredient shall be determined to two

significant figures (see 6.5).

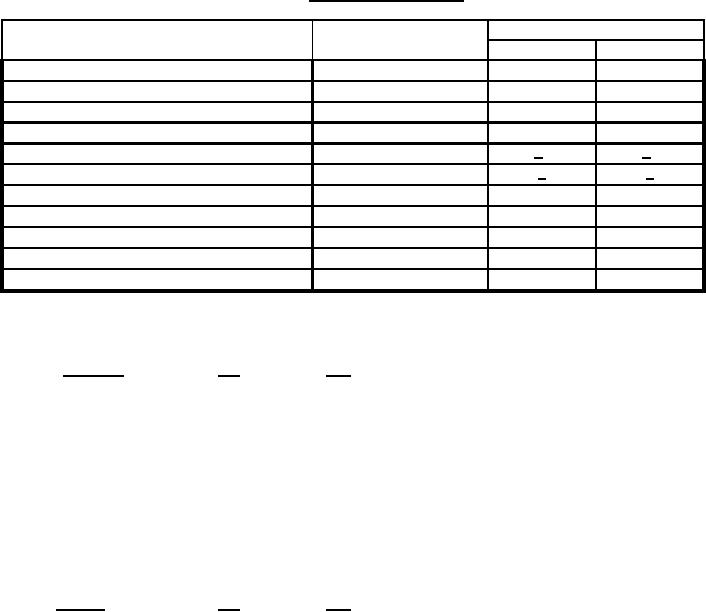

TABLE I. PBXN-110 formulation.

Percent by Weight

Ingredient

Specification

Type I

Type II

1

1

HMX, Grade B, Class 3

MIL-DTL-45444

66.0

66.0

1

1

HMX, Grade B, Class 2

MIL-DTL-45444

22.0

22.0

2

2

Polybutadiene, linear, hydroxyl-terminated

WS 23148

5.378

5.365

2

2

Isodecyl pelargonate

AS 2328

5.378

5.365

3

4, 4'-Methylenebis(2,6-di-tert-butylphenol)

DOD-M-82730

0.05 + 0.005

0.05 + 0.005

Lecithin

MIL-L-3061

0.70 + 0.05

0.70 + 0.05

2

Polymethylene polyphenylisocyanate

WS 22348 Type I

0.494

--

2

Isophorone diisocyanate

WS 16305

--

0.510

4

Dibutyltin dilaurate (DBTDL)

DOD-D-82727

--

0.01

4

Ferric acetylacetonate (FeAA)

OS 9804

--

0.0015

4

Dibutyltin sulfide (DBTS)

WS 22349

--

0.10

1

The weight ratio of the HMX Class 3 to HMX Class 2 is nominally 3:1. To accommodate lot-to-lot variations

in the HMX classes (see 6.6), this weight percent ratio is allowed to vary from a minimum of 1:1 to a

maximum of 8.78:1. These ratios will result in the following minimum and maximum weight percentages:

Ingredient

Min.

Max.

HMX Class 3

44.0

79.0

HMX Class 2

9.0

44.0

in such a way that the total HMX content remains between 86 percent and 89 percent (see 3.3).

2

These are nominal values assigned to these component materials. The nominal composition of PBXN-110,

Type I and Type II, was derived using the values of the sample calculations (6.5.1) and the requirements of

3.3.2. Actual weight percents of these materials must be calculated in accordance with 3.3.2 using

experimentally determined equivalent weights.

3

Exception to DOD-M-82730: The maximum melting point requirement for 4,4'-Methylenebis(2,6-di-tert-

butylphenol) shall not apply.

4

Use either DBTDL, FeAA, or DBTS. The tolerances on the weight percent of the catalysts shall be:

Min.

Max.

Catalyst

DBTDL

0.002

0.02

FeAA

0.001

0.02

DBTS

0.03

0.30

3.4 Cured explosive requirements. The cured explosive shall meet the requirements of table II

when tested in accordance with section 4 (see 6.7).

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business