MIL-DTL-757C

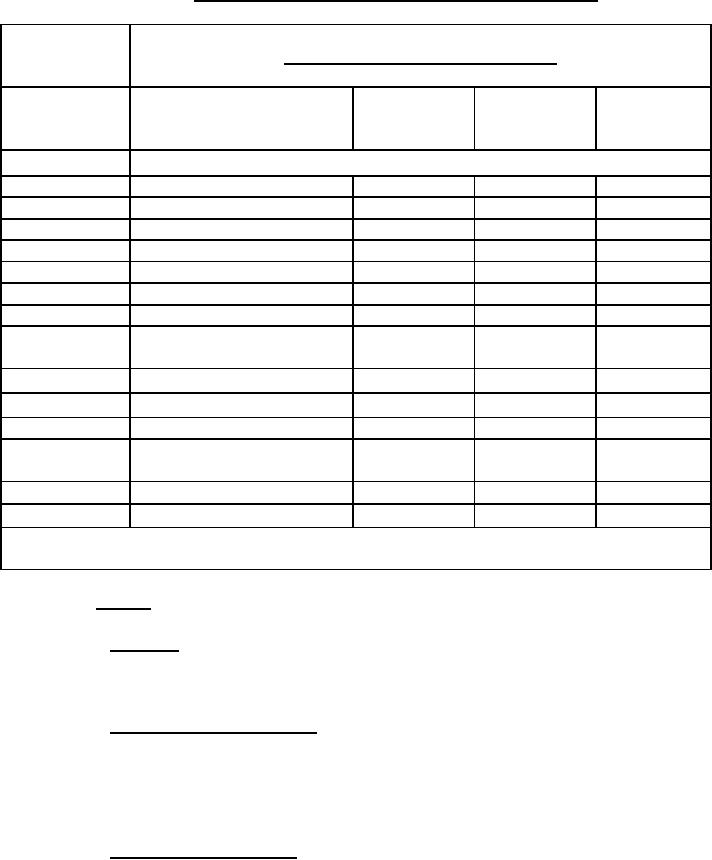

TABLE IV. Conformance inspection classification of characteristics.

Chemical and physical characteristics

Inspection

Conformance

Requirement

Classification

Examination or Test

Method

Criteria

Paragraph

Reference

Critical

None defined

Major

101

Appearance

4.3.3.2

3.2

4.4.2

102

Crystal form

4.3.3.2

3.3

4.4.3

103

Crystal dimensions

4.3.3.2

3.4

4.4.4

104

Granulation

4.3.3.3

TABLE I

4.4.5

105

Apparent density

4.3.3.2

TABLE I

4.4.6

106

Acidity

4.3.3.2

TABLE I

4.4.7

Material insoluble in

4.3.3.3

107

TABLE I

4.4.8

ammonium acetate

4.3.3.3

108

Material soluble in ether

TABLE I

4.4.9

4.3.3.3

109

Lead

TABLE I

4.4.10

110

Nitrogen

4.3.3.3

TABLE I

4.4.11

Instantaneous flash point

4.3.3.3

111

TABLE I

4.4.12

(DSC)

Minor

100%

201

Lot numbering

3.6

4.4.13

Notes:

4.3.3 Testing. (see 6.6)

4.3.3.1 Sampling. Obtain two random 30 g samples from each batch of normal lead

styphnate being submitted for inclusion in a lot. The samples shall be obtained from the process

vessel prior to pack out using procedures described in ASTM E300 for slurries.

4.3.3.2 Testing for batch acceptance. One sample obtained according to 4.3.3.1 from

each batch shall be tested in accordance with applicable test methods for conformance with

requirements of appearance (see 3.2), crystal form (see 3.3), crystal dimension (see 3.4),

apparent density (see TABLE I), and acidity (see TABLE I). If any sample fails to meet any of

these requirements, the batch represented by the sample shall be rejected.

4.3.3.3 Testing for lot acceptance. The second samples from the batches not rejected

under provisions of 4.3.3.2 shall be placed in a suitable container of sufficient volume to hold a

composite sample from all batches in the lot. The composite sample shall be thoroughly mixed

to assure homogeneity, and two sub-samples of approximately 30 g each shall be obtained from

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business