MIL-DTL-398D

4.7.7.3 Analysis of RDX samples and standards. Prior to the

analysis of either RDX samples or standards, the pumping of

mobile phase through the system shall be initiated at a flow rate

of 1.5 milliliters per minute. The HPLC system shall be allowed

to equilibrate at ambient conditions for approximately 10 minutes

or until the flow of mobile phase and the output reading on the

UV detector are stable. After the HPLC system has stabilized,

the sample loop on the HPLC injector system shall be filled with

an aliquot of the RDX sample or standard. Using either manual or

automated injection techniques, the aliquot of sample in the 20

microliter sample loop on the injector should be transferred to

the HPLC column. The peak area data from the HPLC chromatogram

for the HMX component in the samples and standards should be

calculated and retained using the data collection system (i.e.

computer, computing integrator, etc.).

4.7.7.4 Preparation and analysis of RDX calibration

standards. Calibration standards having the approximate

concentrations provided in Table IV shall be prepared. The RDX

and HMX used in the calibration standards shall have a minimum

purity of 99.9%. Prepare the calibration standards by weighing

the RDX and HMX components to the nearest 0.0001 gram in tared

250-ml glass volumetric flasks with ground glass stoppers. Add

approximately 100 milliliters of HPLC grade acetone to the

flasks. Cap the flasks and place the standards in an ultrasonic

bath for 10 minutes or until the RDX and HMX are completely

dissolved and uniformly mixed. Allow the standard mixtures to

cool to ambient temperature, and then fill to the mark of the

volumetric flasks using HPLC grade acetone.

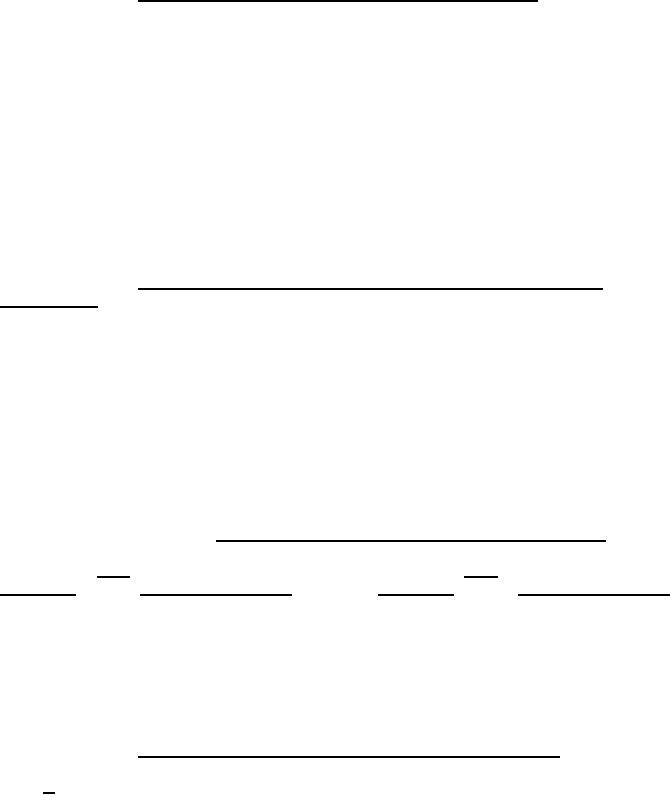

TABLE IV.

Composition of the RDX/HMX Standards

RDX

HMX

Percent

Weight (grams)

Percent

Weight (grams)

96.0

0.4800

4.0

0.0200

89.5

0.4475

10.5

0.0525

83.0

0.4150

17.0

0.0850

Each calibration standard which is prepared shall be tested using

the conditions and methodology outlined in 4.7.7.1 and 4.7.7.3.

4.7.7.5 Preparation and analysis of RDX samples. Dry

approxio ately 1 gram of the RDX sample to be tested in an oven at

m

100 + 5 C for a minimum of one hour. Using an analytical

balance, weigh approximately 0.05 gram of the dried RDX to the

nearest 0.0001 gram in a clean, glass 30-ml bottle with a Teflon

lined lid. Add 25.0 milliliters of HPLC grade acetone to the

bottle using an automatic repipette. Cap the bottle and place

the samples in an ultrasonic bath for 10 minutes or until the RDX

is completely dissolved and the solution is uniformly mixed.

16

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business