MIL-DTL-14970D

or metal chips, etc., and that the safety and reliability of

the explosive are not compromised. Compliance with this

requirement shall be as specified in 4.6.8.

3.5 Product certification. No Composition A-5 material

whether produced for military or commercial use may be

represented as meeting the requirements of this detail

specification unless it complies with all requirements

contained in Section 3. The process control document (see

3.3), test data for first article inspection (see 4.4) and

conformance inspection (see 4.5) shall be submitted to the

Technical Agency (see 6.13) for evaluation, approval and

certification on compliance with MIL-DTL-14970. (See 6.11).

4.

VERIFICATION

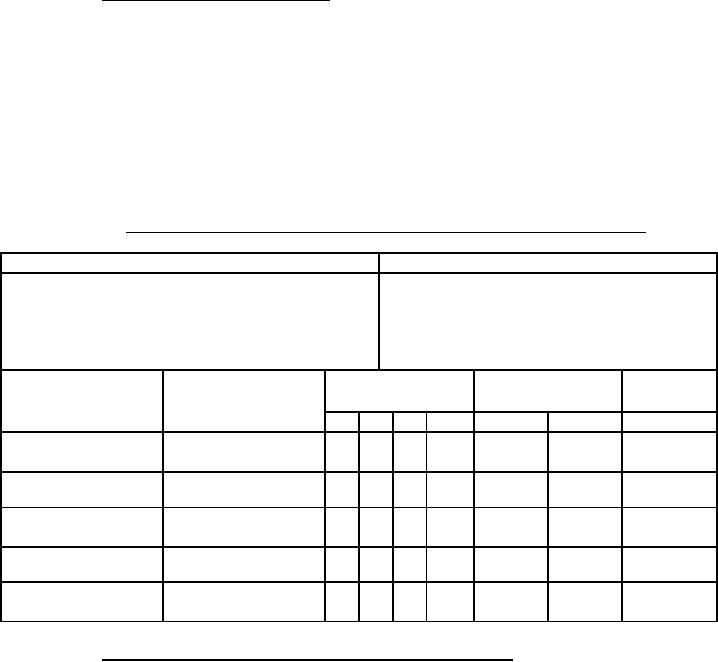

TABLE II. REQUIREMENTS/VERIFICATION CROSS REFERENCE MATRIX

METHOD OF VERIFICATION

CLASSES

OF

VERIFICATION

1-

Analysis

A - First

Article

2-

Demonstration

(end item test)

3-

Examination

B - Conformance

4-

Test

Verification

Verification

Section

Section 3

Description

Method

Class

4

Requirements

123

4

A

B

First

3.1

X

X

X

X

4.4

Article

3.2

Material

X

X

X

X

X

4.6

Process

3.3

X

X

4.1

controls

3.4

Workmanship

X

X

X

4.6.8

Product

3.5

X

X

X

4.4/4.5

certification

4.1 Submission of process control document. A Process

Control Document shall be submitted to the Technical Agency

(see 6.14). The document shall contain a description of the

process, all materials used, process conditions/procedures

and production/inspection equipment used to produce

Composition A-5 meeting the requirements of this

specification (see 6.3). In addition, whenever there is a

change that requires lot interfix change (per MIL-STD-1168)

such as the source of material, process conditions,

procedures, etc. from those in the previous process control

document, the Technical Agency (see 6.13) shall be notified

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business