MIL-E-82756(OS)

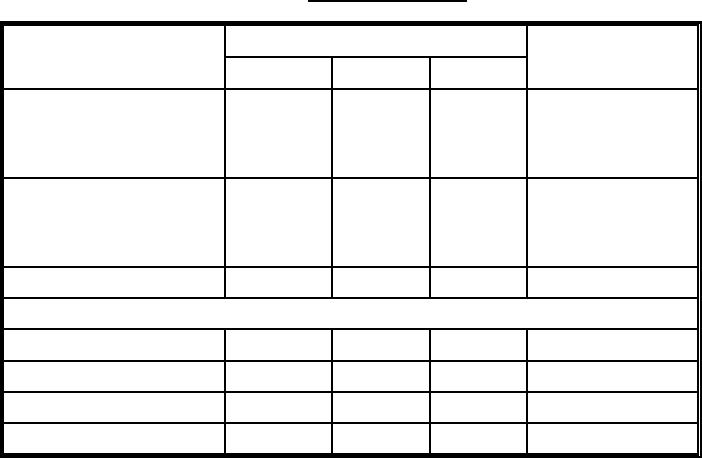

TABLE I. PBXN-103 formulation.

Ingredient

Percent by Weight

Specification

Theoretical

Minimum

Maximum

Pelletized nitrocellulose

6.0

6.0

7.5

WS 12799, Grade A,

(PNC) (percentage as

Type I or II, Classes 2

nitrocellulose)1

or 3, 1-30 second

viscosity

Ammonium perchlorate (AP)

40.0

38.0

42.0

WS 18485, WS 12794,

MIL-A-192, Grade C,

Class 4, or WS 12236,

Class 1

Aluminum

27.0

25.0

29.0

MIL-A-82728

Mixed Plasticizer

Resorcinol

0.2

0.2

0.4

MIL-R-22578

MTN

23.0

21.0

25.0

WS 12798

TEGDN

2.5

2.0

3.0

WS 12797

EC1

1.3

1.3

1.7

MIL-E-255, Class 3

1

WS 12799, Pelletized Nitrocellulose will contain EC. The amount of PNC used must account for the

fact that part of it is EC. The composition limits are a minimum of 6.0 and a maximum of 7.5 percent

nitrocellulose. The EC percentage in the mixed plasticizer must be adjusted (reduced) by the amount

added with the PNC.

3.3.2 Tensile strength. Tensile strength shall be determined using either a cut or cast sample of

PBXN-103. Tensile strength of a cut sample of PBXN-103 shall be greater than 60 pounds per square inch

(psi) when determined as specified in 4.6.5.1. Tensile strength of a cast sample of PBXN-103 shall be

greater than 90 psi when determined as specified in 4.6.5.2. Strain at maximum stress for cut and cast

samples shall not be less than 9 percent.

3.3.3 Vacuum stability. The PBXN-103 vacuum stability shall not exceed 1.00 mL/g in 40 hours at

100ĚC when tested in accordance with 4.6.6.

3.4 Workmanship. The PBXN-103 explosive shall be free from foreign materials and shall be

manufactured in a manner to assure compliance with all the requirements of this specification. The

workmanship exhibited in the first article sample shall be evaluated to determine acceptability. The

approved standards of workmanship will thereby become a minimum requirement for all material offered

for acceptance.

4. QUALITY ASSURANCE PROVISIONS

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business