MIL-E-82886(OS)

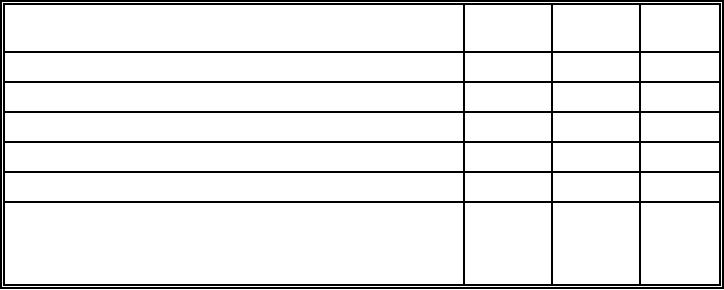

Test

Property

Minimum

Maximum

Method

Density, gram per cubic centimeter (g/cc) (at 25 degrees Celsius (ĚC))

1.60

1.70

4.6.1

Stress (maximum) pounds per square inch (at 25ĚC)

60

--

4.6.2

Strain, maximum stress, % (at 25ĚC)

12

--

4.6.2

Hardness, Shore A (at 25ĚC) (30 seconds)

30

--

4.6.3

Vacuum stability (at 100ĚC) milliliter (mL) gas/g/48 hours

--

0.5

4.6.4

Average composition:

4.6.5

% RDX

62.0

66.0

% Aluminum powder, spherical

18.0

22.0

% Binder

14.0

18.0

3.5 Workmanship. The explosive material shall be free from foreign materials and manufactured in

a manner to ensure compliance with all of the requirements of this specification. The workmanship

exhibited in the first article sample will be evaluated to determine acceptability. The approved standards

of workmanship will thereby become a minimum requirement for all units offered for acceptance.

3.6 Classification of characteristics. Characteristics verified by the inspections and tests specified

herein are classified as Critical, Major and Minor in accordance with DOD-STD-2101. Critical

characteristics are identified by the symbol (C) and Major characteristics by the symbol (M). The number

following the classification symbol indicates the serial number of the characteristics. Characteristics not

annotated by the classification code symbol are classified as Minor.

4. QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. Unless otherwise specified in the contract or purchase order (see

6.2), the contractor is responsible for the performance of all inspection requirements (examinations and

tests) as specified herein. Except as otherwise specified in the contract or purchase order, the contractor

may use his own or any other facilities suitable for the performance of the inspection requirements

specified herein, unless disapproved by the Government. The Government reserves the right to perform

any of the inspections set forth in this specification where such inspections are deemed necessary to ensure

supplies and services conform to prescribed requirements.

4.1.1 Responsibility for compliance. All items shall meet all requirements of sections 3 and 5. The

inspection set forth in this specification shall become a part of the contractor's overall inspection system or

quality program. The absence of any inspection requirements in the specification shall not relieve the

contractor of the responsibility of ensuring that all products or supplies submitted to the Government for

acceptance comply with all requirements of the contract. Sampling inspection, as part of manufacturing

operations, is an acceptable practice to ascertain conformance to requirements, however, this does not

authorize submission of known defective material, either indicated or actual, nor does it commit the

Government to accept defective material.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business